-

We will provide the

best Industrial service -

We will provide the

best Industrial serviceWe are the best guarenteed company to serve you. We are dedicated to help you any time. -

We will provide the

best Industrial serviceWe are the best guarenteed company to serve you. We are dedicated to help you any time.

Smart Production

it is a new production technology that aims at collaboration between operator-Assets-tools

Smart Service

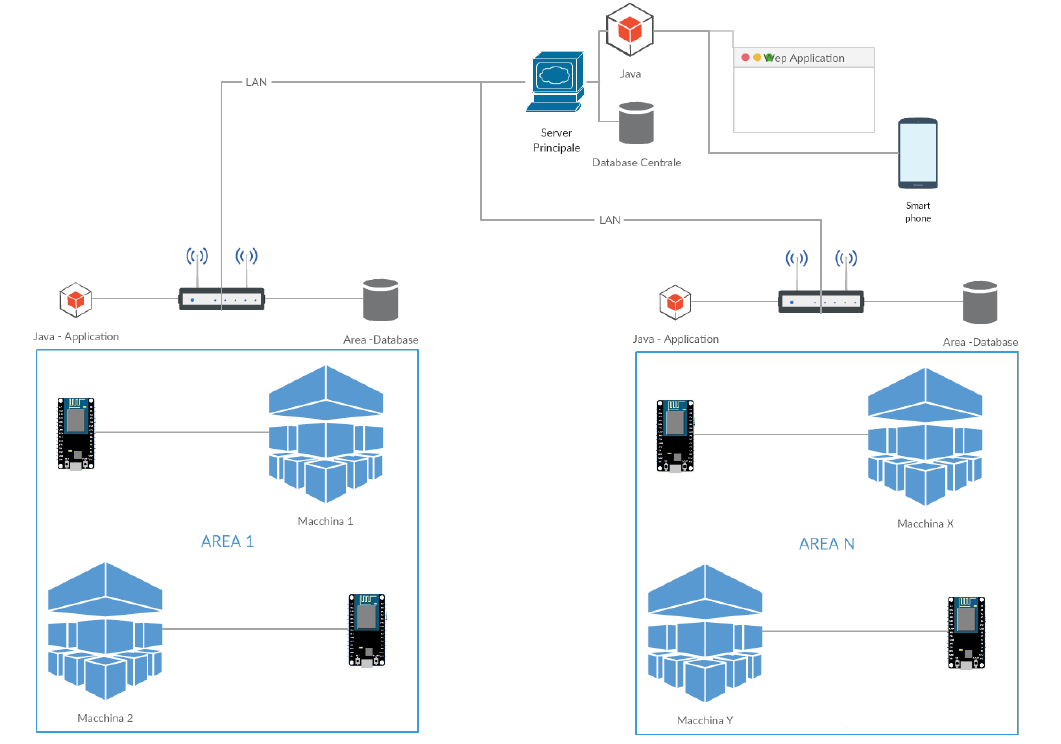

is an "integrated infrastructure" that can be installed on a specific server, interact with the corporate network infrastructure, communicate with Hubs, other servers, other systems

Smart Energy

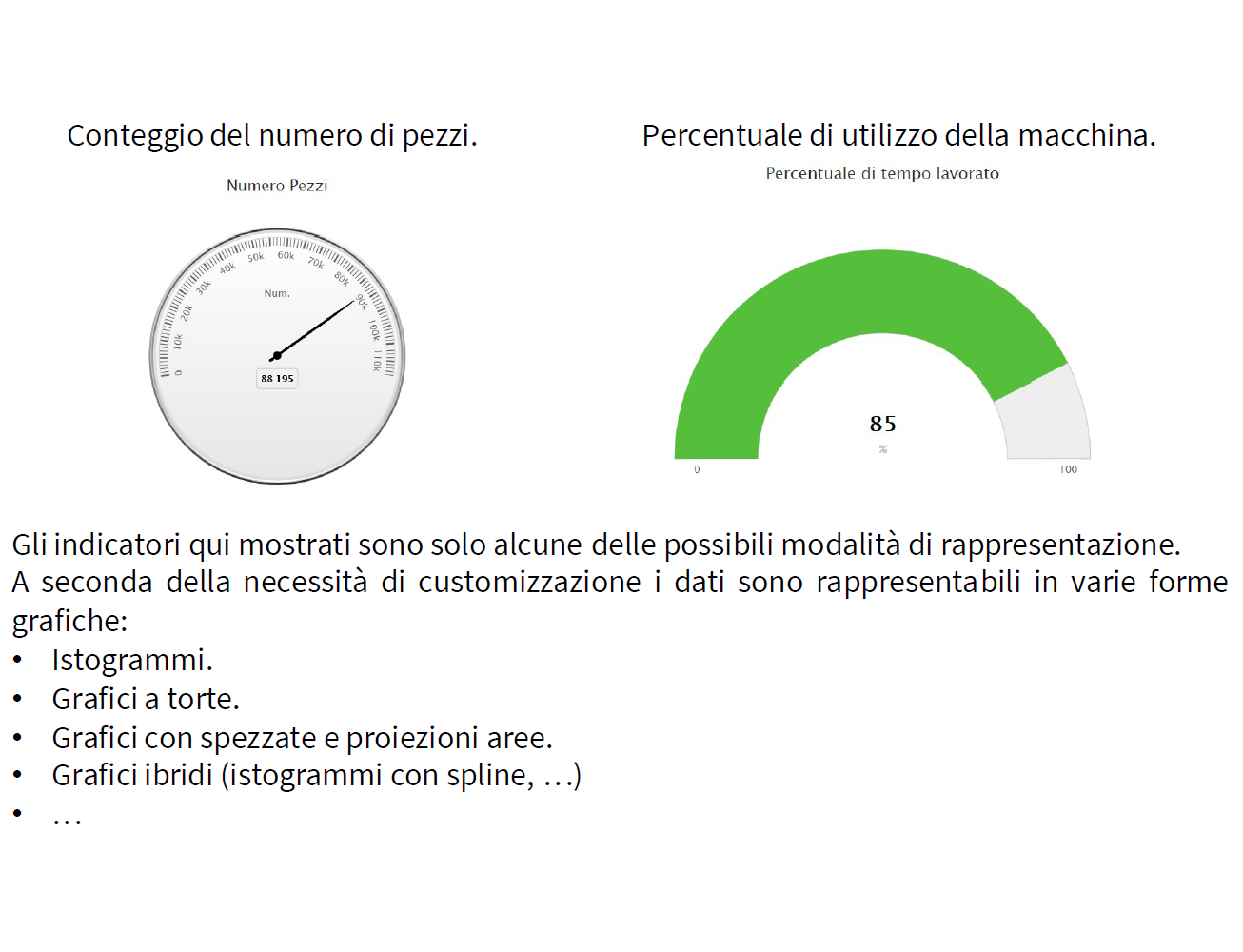

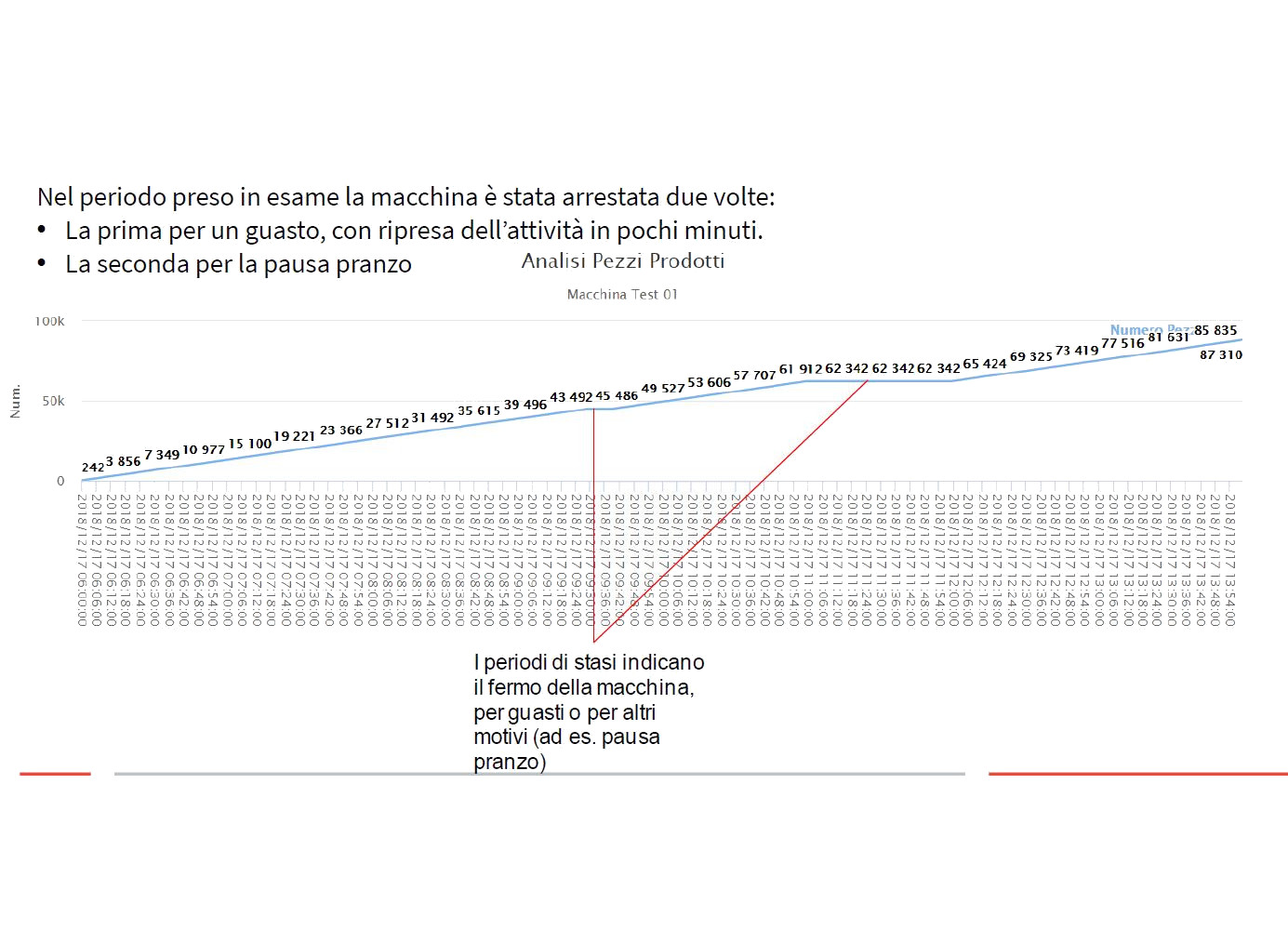

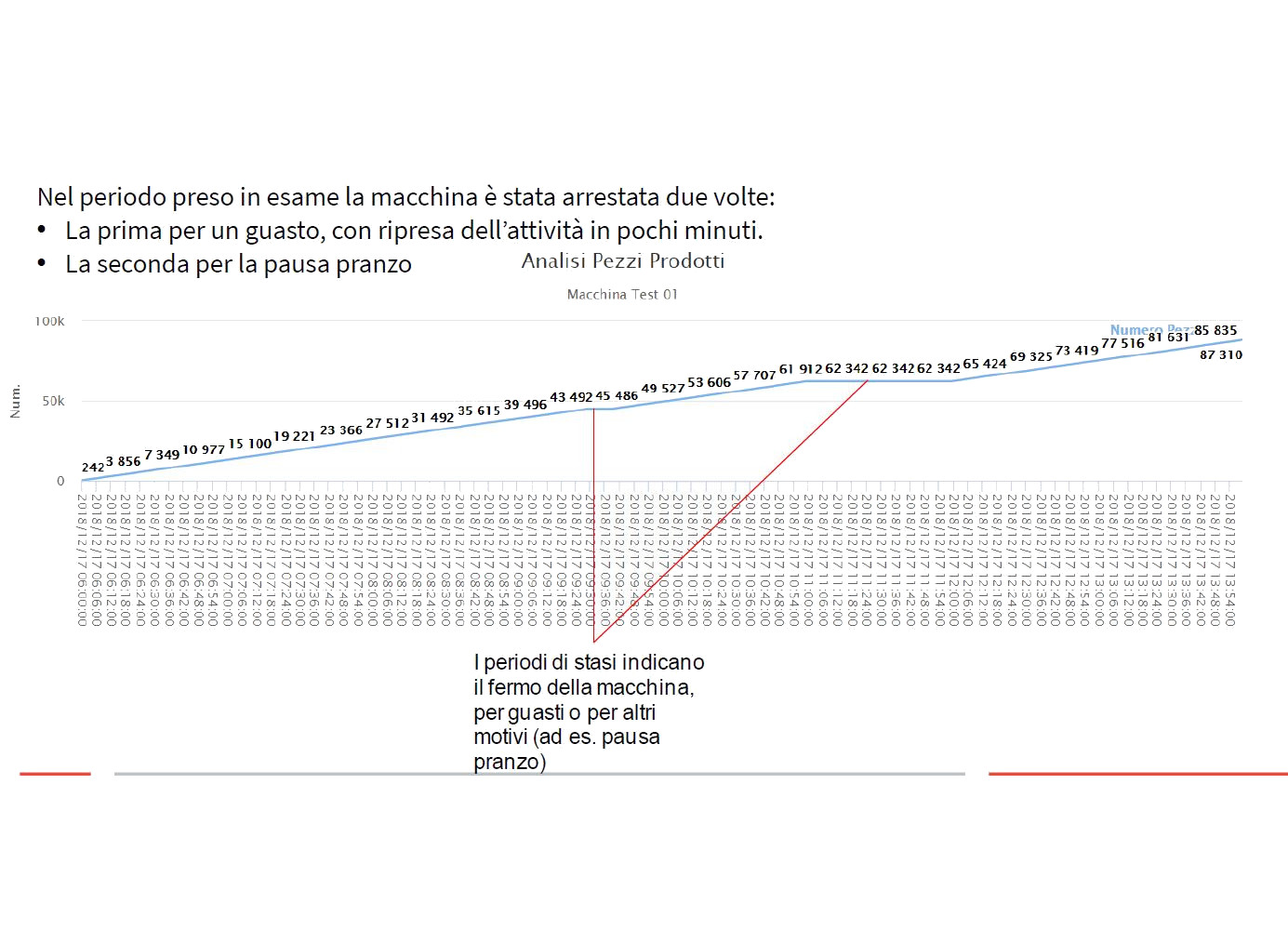

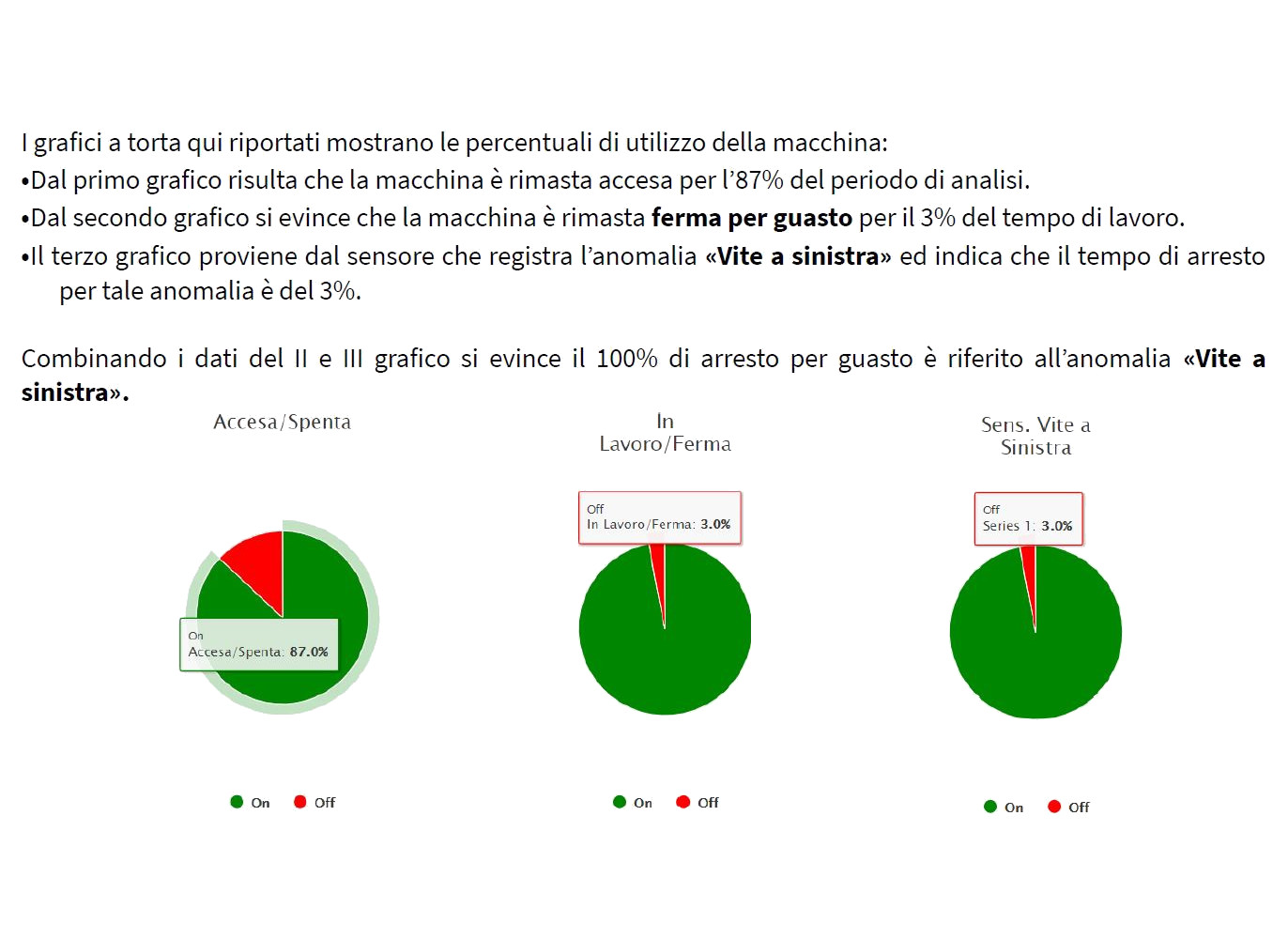

performs a statistical analysis aimed at the efficiency of production in terms of pieces produced, percentage of worked time, log of digital inputs / outputs

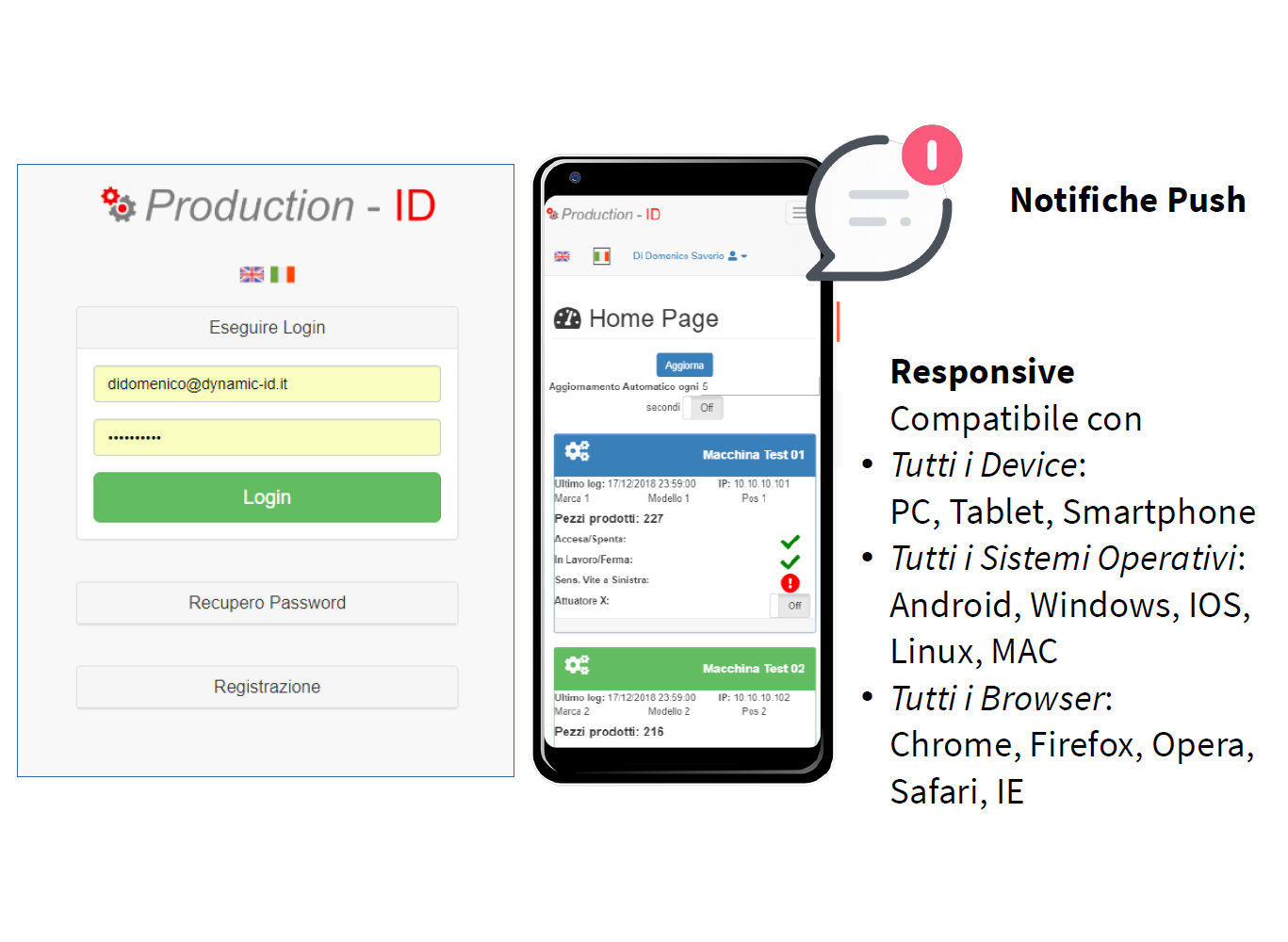

The Production-ID system is a monitoring system for production lines oriented to the automation model of the Industry 4.0 .

It turns the attention of the analysis of the data and the users towards the three fundamental concepts of the Smart Factory: Smart Service - Smart Energy - Smart Production

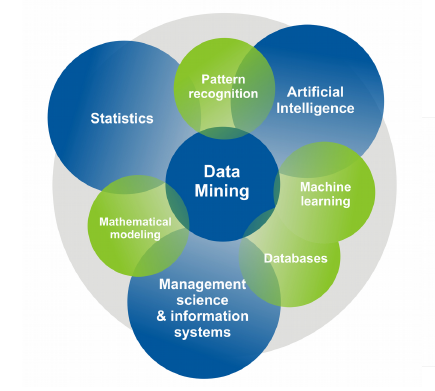

It is a hardware and software system for the real time monitoring of production plants.

Through the system it is possible to monitor and record the status of all plants / Assets in the plant and activate procedures in case of fault or downtime .

Monitoring (real-time):

- State of Production of Assets

- Process Parameters of the Assets

- Product Quality

Detection (real-time):

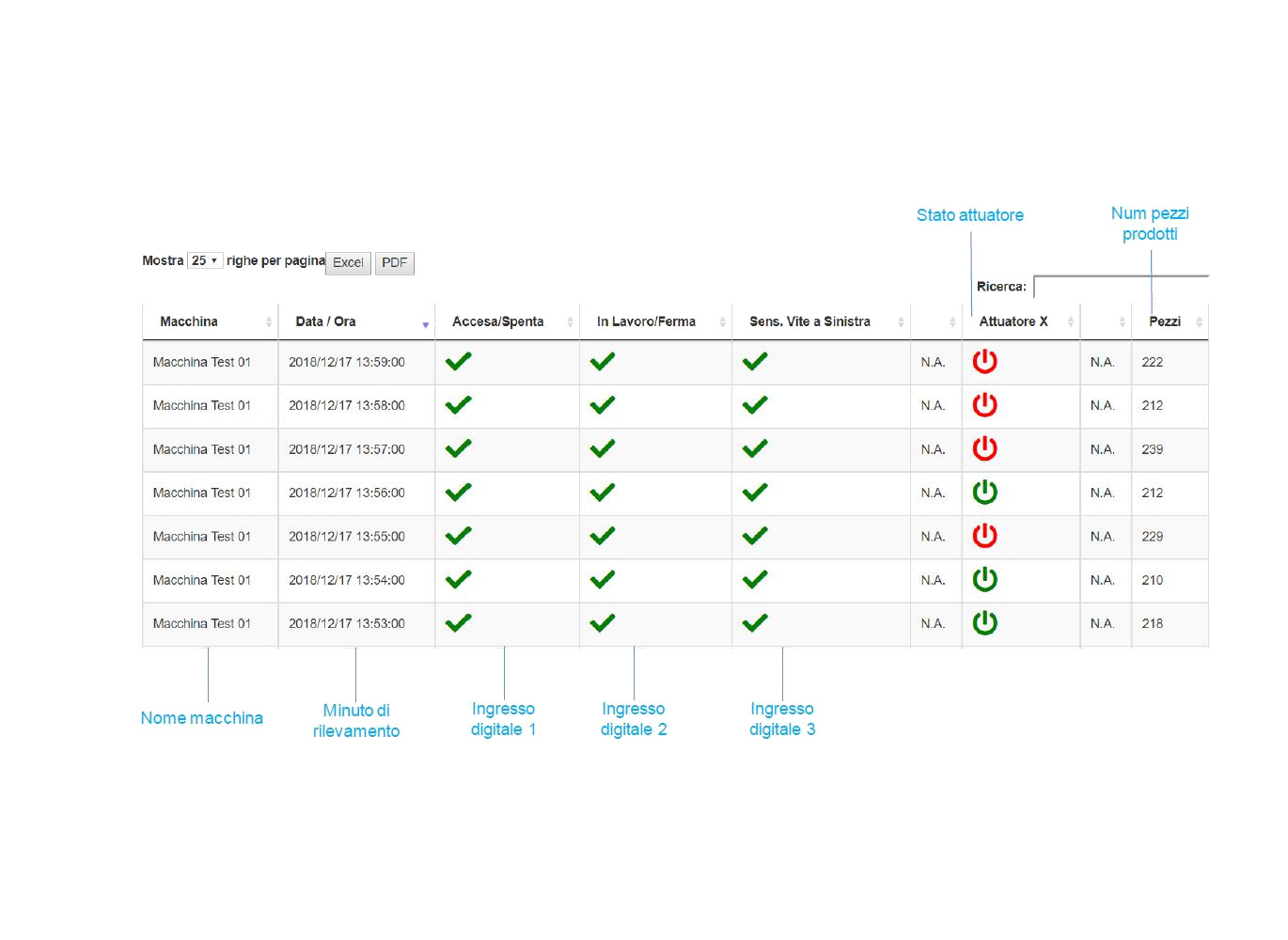

- Asset Status

- Operator (Rfid Tag)

- Order (Barcode or Rfid)

- Number of Produced Pieces

- Number of Expected Pieces

- Sensor Status

Process Parameters

The hardware controllers integrated natively in the software allow the monitoring of Process Parameters such as:

Run Time durationSetup Time duration

Emergency Requests

Configurable Data Refresh Rate

Actuators Status

Quality Control

The system integrates Quality Control tools which:

Approval initiation processingChecks of the flying inspectors' checks

Direct data entry for product traceability

Data entry for object capability variables (Cp and Cpk)

Data entry for X-R card feeding

Classification of the non-compliant product

- System Overview

- Modules

- Working

- Reports

Request a Quote

Fill out the form indicating your needs